Parts List

In addition to the 3D printed parts, the following parts must be obtained separately by the modeller:

- For pre 2017 Models only - 2 brass I-beams (Special Shapes Part No. B-6-3)

- Brass wire for handrails, etc. (0.4 mm, 0.6 mm)

- Brass chain (40 links per inch) if modelling original version with chain "handrails" e.g. North Yard CH40 (2 packs required per loco)

- Air hoses - e.g. Detail Associates #6206 (Vacuum brake hoses are included.)

- Handrail Posts (4) for uncoupling levers - e.g. Markits 1.5 mm(short - available from Railwest Models.

- Bogie drive mechanisms - see below (Hollywood Foundry)

- Motor - Mashima 1833D Flat Can (double shaft, 2 mm diameter, includes fixing screws) (Hollywood Foundry)

- Drive shaft(s) - 1.5 mm diameter, 65 mm long (cut to exact length) (Hollywood Foundry)

- Universal Joint set for 1.5 mm shafts (Hollywood Foundry)

- Flexible coupling(s) for motor end(s) of drive shafts - suggestion is to use model aircraft fuel tubing, approx. 1 mm ID, 4 mm OD.

- DCC decoder and speaker (both optional)

- Light Emitting Diodes (LEDs) for headlights 4 x 3 mm (sunny white)

- LEDs (red and white) and optic fibre, if operating marker lights desired

- paint as desired

- lead or other weighting material

- Kadee couplers #156 ("scale") or #146 (normal size)

- Kadee draft gear boxes #252

- Fixing screws for body, couplers and fuel tank e.g. Kadee #256 - 12 holes are included correct size (1.8 mm) ready for tapping 2-56.

- Fixing screws for speaker M1.4 x 6 (slightly longer is OK) - 4 holes are included correct size (1.1 mm) and screws should make their own thread, tapping shouldn't be required. Suitable screws are available from DCC Concepts - Part No. DCS-PHB156 or in assortment DCS-PHBSet. Although described as 1.5 mm, the DCC Concepts screws are actually M1.4 thread. Note: DCC Concepts now supplies pan-head and countersunk screws interchangeably, so you can't be sure of getting one or the other.

Bogie Drive Mechanisms

The bogie drive mechanisms can be ordered direct from Hollywood Foundry. The ordering specifications are as follows:

Drive bogie specifications: G16.5/B28.6+25/W14-110/15:

Dummy bogie specifications: G16.5/B28.6+25/W14-110/

To order the above bogie configurations, please use the special order page on the Hollywood Foundry web site and copy and paste the above codes into the Product Description field.

If a single drive bogie is fitted, this would normally be placed at the rear to keep the cab free for interior detailing if desired. However, the drive shaft is quite low above the footplate level, so there is minimal intrusion into the cab when two drive bogies are fitted.

The current (February 2016) pricing for the required Hollywood Foundry parts is:

Dummy bogie - $52.80 (same price as Bullant 3-axle Dummy)

Drive shafts are available from Hollywood Foundry although the required 65 mm length is not a standard product. Check with Hollywood Foundry for availability. Alternatively, 1.5 mm brass or steel rod can be used.

Drive bogie specifications: G16.5/B28.6+25/W14-110/15:

Dummy bogie specifications: G16.5/B28.6+25/W14-110/

To order the above bogie configurations, please use the special order page on the Hollywood Foundry web site and copy and paste the above codes into the Product Description field.

The modeller has the choice of fitting two identical drive bogies or one drive bogie and a matching dummy bogie, depending on the required hauling capacity.

If a single drive bogie is fitted, this would normally be placed at the rear to keep the cab free for interior detailing if desired. However, the drive shaft is quite low above the footplate level, so there is minimal intrusion into the cab when two drive bogies are fitted.

Drive bogie - $91.30 (same price as Bullant In-Line 3-Axle)

Dummy bogie - $52.80 (same price as Bullant 3-axle Dummy)

Motor: Mashima M1833D - $31.35

Universal Joint Set for 1.5 mm shafts (set contains parts for 4 joints. 1 joint is required per drive bogie, but it is recommended to purchase 1 set per loco to allow for some "spares".) - $4.19 per set

|

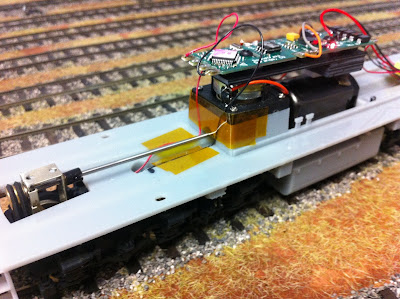

| The prototype 3D-printed chassis showing central motor, Tsunami AT-style DCC sound decoder, drive shaft, belt drive and speaker "duct" with tunnel for drive shaft. |

The chassis does not have provision for a flywheel. The main reason is that the motor is mounted low down, partly in the fuel tank, to get a "straight line" drive shaft alignment. Also, the speaker is very close to one end of the motor, which was necessary to avoid the narrow part of the body just behind the cab.

The chassis is specially designed to accept a 23 mm square high-bass speaker (Soundtraxx 810129 or equivalent) if a sound decoder is to be installed. The speaker faces downwards on a "sound duct" which has a "tunnel" through it for the front drive shaft.

DCC and Sound

Although the choice of specific sound decoder is very subjective, the Soundtraxx Alco 244 Tsunami decoder sounds similar to the English Electric diesel engine in the prototype, and is probably the closest available "off-the-shelf" decoder. The Tsunami "AT" style decoder model 828043 (pictured above) is suitable and slightly cheaper than the TSU-1000 style model 827104.

Note: The above links are for the SoundTraxx web site. SoundTraxx do not sell direct but their products are available from many retailers.

The suggested couplers are both "long shank" style which avoids the problem of the "glad hand" on opposing couplers from fouling the cowcatcher. The choice between normal and "scale" size is up to the individual modeller.

Also, the suggested Kadee #252 draft gear boxes should be mounted upside down (as per the photo on the right on the Kadee web site). The round boss on the upper side needs to be trimmed away to allow the assembled coupler to slide into the headstock opening.

Other types of couplers can potentially be installed by modifying the headstock and/or coupler mounting pad.

As delivered, the R class had round handrail posts with chain between them rather than solid handrails. This was a feature of the R class and was necessary to allow the doors on the side of the long hood to be opened.

Later, the chains were replaced with solid handrails but with removable segments to allow the doors to be opened.

The 3D-printed chassis incorporates slots intended to house 2 mm x 0.25 mm brass strip soldered to the bottom of each handrail post, of which there are 25. This approximates the prototype bracket arrangement and allows the handrail posts to be positioned right at the edge of the footplate.

The handrail posts can be made from 0.6 mm brass wire and should be 16.7 mm high. The brass strip should be soldered to the bottom of each post, with 1.1 mm overlap, and project a maximum of 1.8 mm below the bottom of the handrail post. A suggested construction method is to leave the brass wire and strip as long lengths, and tape them down to a heat resistant surface with the required overlap, then solder the joint and trim both to the required length. The brass strip will probably require filing to remove any rough edges prior to insertion into the slots in the chassis.

Suitable chain is available from North Yard in New Zealand, part number CH40 (300 mm length). Two packs are required per loco. Railwest Models normally stock this chain also.

Note: The above links are for the SoundTraxx web site. SoundTraxx do not sell direct but their products are available from many retailers.

Couplers

Also, the suggested Kadee #252 draft gear boxes should be mounted upside down (as per the photo on the right on the Kadee web site). The round boss on the upper side needs to be trimmed away to allow the assembled coupler to slide into the headstock opening.

Other types of couplers can potentially be installed by modifying the headstock and/or coupler mounting pad.

Handrails and Chains

Later, the chains were replaced with solid handrails but with removable segments to allow the doors to be opened.

The 3D-printed chassis incorporates slots intended to house 2 mm x 0.25 mm brass strip soldered to the bottom of each handrail post, of which there are 25. This approximates the prototype bracket arrangement and allows the handrail posts to be positioned right at the edge of the footplate.

The handrail posts can be made from 0.6 mm brass wire and should be 16.7 mm high. The brass strip should be soldered to the bottom of each post, with 1.1 mm overlap, and project a maximum of 1.8 mm below the bottom of the handrail post. A suggested construction method is to leave the brass wire and strip as long lengths, and tape them down to a heat resistant surface with the required overlap, then solder the joint and trim both to the required length. The brass strip will probably require filing to remove any rough edges prior to insertion into the slots in the chassis.

Suitable chain is available from North Yard in New Zealand, part number CH40 (300 mm length). Two packs are required per loco. Railwest Models normally stock this chain also.

Chassis - Removal of Support Material

Carefully cut away the support materials from the delicate areas highlighted in the drawing below which are:

- Bolsters with bogie chain brackets approx. 6 mm in from edge of footplate (2 per side)

- Triangular footplate supports (4 per side)

- Sandboxes (2 per side)

Once these areas have been done, the remainder of the support material can be gently torn away by wiggling a section of it to break the fine attachment points.

The remnants of the support attachment points should be removed with a sharp hobby knife, filing or sanding on all visible areas, including the bogie attachment points.

Chassis - Assembly of Brass I-Beams (Pre 2017 Models Only)

From 2017, the I-Beams are included in the 3D-printed chassis. The brass I-Beams are not required.

The underside of the chassis includes two longitudinal slots which are designed to provide a secure attachment for the brass I-beams. The brass I-beams add some weight and rigidity to the chassis, as well as replicating the appearance of the steel I-beams in the prototype chassis.

Cut the brass I-beams to a length of 236 mm, or a fraction under. The I-beams should fit between the inside of the headstocks with a small amount of room at each end so that they do not exert any outward pressure on the headstocks. Keep the offcuts as they will be useful for checking the fit of the I-beams in the mounting slots.

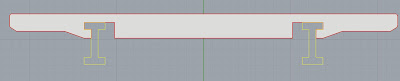

At this stage, it is advisable to cut 3 notches in the lower inside flange of each I-beam to facilitate later access to the fixing screws which attach the chassis to the body. The suggested shape of the notches is highlighted in yellow below.

The diagram below is a cross-section of the footplate, with the I-beams highlighted in yellow. The intention is that the I-beams are inserted into the slots, then slid outwards so that the flange on the I-beam engages in the groove to provide a secure attachment.

Once the support materials have been removed from the underside of the chassis, it will be necessary to do some cleaning up of the I-beam slots. Firstly, check for any remnants of supports materials on the inside surfaces of the slots and, in particular, in the narrow groove. Cut away any remnants with a sharp hobby knife.

After filing any burs from the cut end of an offcut of I-beam, test fit it to see whether it will slide into the groove at various locations along the length of the chassis. Moderate pressure with a screwdriver will probably be required to encourage the I-beam to slide sideways into the groove. If there are tight spots, don't force it at this stage, as the groove will probably require cleaning out.

It may be necessary to make a tool from metal strip approx. 6 x 0.5 mm, by bending the first 3 mm from the end of the strip at right angles. Insert the bent end of the tool into the groove and slide it along to find and remove any remnants of plastic support material which may be obstructing the groove. Be careful not to damage the triangular supports under the footplate, the bolster ends or sandboxes.

Once the groove has been cleaned out so that the offcut of I-beam fits at any point along it, insert the full-length I-beam and gently slide it sideways to engage in the groove. When satisfied that the I-beam is fully engaged in the groove along its full length and the notches in the lower flange are aligned with the fixing screw locations, it can be glued in position.

The finished height of the footplate should be 23 mm. Spacers with a nominal thickness of 1 mm are required between the Hollywood Foundry bogies and the underside of the footplate. The thickness of the spacers can be varied slightly, if required, to adjust the coupler height to match a Kadee coupler height gauge.

Chassis Height

The finished height of the footplate should be 23 mm. Spacers with a nominal thickness of 1 mm are required between the Hollywood Foundry bogies and the underside of the footplate. The thickness of the spacers can be varied slightly, if required, to adjust the coupler height to match a Kadee coupler height gauge.