Parts List

- Bogies: e.g. "100-ton roller bearing" by Kadee part no 569 or 1569 (see below) or Tichy #3009 (1 pair) or #3036 (10 pairs)

- Couplers: Kadee #148 or #158 (see below)

- Replacement Metal Wheelsets 36" diameter - if using Tichy bogies, e.g. Intermountain #40051 (4 per wagon).

- Coupler boxes: Kadee #262 (supplied)

- Air Brake Hoses, e.g. Detail Associates #6206

- Brass wire: 0.4 mm for handrails, etc.

- Fixing screws: 2 x 2-56 x 8 mm (5/16") metal, 2 x 2-56 x 12 mm (1/2") nylon - (see below)

- Glue, paint, decals

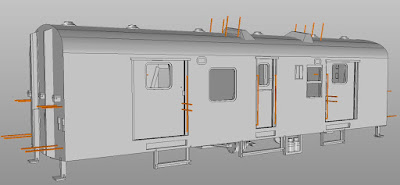

Removing Support Structures

Carefully remove the support structure from the wagon. It is suggested to use a sharp knife to cut the supports away from visible areas. Take particular care around the roofwalk supports at the ends of the wagon, and the discharge hatches at the bottom of the wagon. There should be a row of supports along each side of the wagon, under the side sills. Once these are removed, the supports under the discharge hatches will be visible.

|

| Typical Support Structure prior to removal. |

Go over the model and smooth off any remnants of the fine supports, expecially in the visible areas. A sanding stick or small file can be useful for this.

Bogie and Coupler Mounting Holes

Note: An economical source of steel 2-56 screws in various lengths is Little Bird Electronics.

Bogies

The suggested bogies are Kadee #569 or #1569, the only difference being the width of the wheels. Atlas and Athearn and others make similar bogies, but the advantage of the Kadee ones is that they add some weight to the wagon due to the use of a relatively heavy plastic material.

Tichy Train Group also makes an economical 1-piece plastic bogie #3009 (1 pair) or #3036 (10 pairs), however these are supplied with relatively low quality plastic wheelsets which are also too small in diameter (33"). Intermountain Railway Company sell high quality all-brass wheelsets which fit well in the Tichy bogies and are the correct size, i.e. 36".

Note that Intermountain do also sell complete roller bearing bogies but these are supplied with 33" wheelsets only. Be wary of other brands of bogies as well. In general, US roller bearing bogie (trucks) described as "100-ton" have 36" wheelsets and "70-ton" have 33" wheelsets.

Note that the depth of the blind holes for the bogies is 4 mm. If using Kadee bogies, the supplied screws will need trimming to a length of 7.5 - 8 mm to avoid damaging the wagon (or shorter screws substituted). Do not drill the bogie mounting holes any deeper, as they are directly under the ends of the hopper and the drilled hole will "break through" and be visible on the finished model.

Tichy Train Group also makes an economical 1-piece plastic bogie #3009 (1 pair) or #3036 (10 pairs), however these are supplied with relatively low quality plastic wheelsets which are also too small in diameter (33"). Intermountain Railway Company sell high quality all-brass wheelsets which fit well in the Tichy bogies and are the correct size, i.e. 36".

Note that Intermountain do also sell complete roller bearing bogies but these are supplied with 33" wheelsets only. Be wary of other brands of bogies as well. In general, US roller bearing bogie (trucks) described as "100-ton" have 36" wheelsets and "70-ton" have 33" wheelsets.

Note that the depth of the blind holes for the bogies is 4 mm. If using Kadee bogies, the supplied screws will need trimming to a length of 7.5 - 8 mm to avoid damaging the wagon (or shorter screws substituted). Do not drill the bogie mounting holes any deeper, as they are directly under the ends of the hopper and the drilled hole will "break through" and be visible on the finished model.

Couplers

The WW is designed for Kadee "whisker" couplers. Either the #158 (scale size) or #148 (normal size) couplers can be used, with #262 draft gear boxes.

The draft gear boxes supplied with the couplers do not fit as they have a different mounting hole position. The #262 draft gear boxes, which are available separately, are narrower and have been used because they allow details such as the brake hoses to be positioned the scale distance from the wagon centre line. Also, the #262 draft gear boxes are easier to use as the lid snaps into position.

Because of the deep end sill on the WW series of wagons, the model has been designed so the coupler and draft gear box slides into a recess via a hole in the end sill. Make sure that any remnants of support structure from the 3D printing process have been cleaned up from inside the coupler mounting recess.

The draft gear box will probably be a snug fit inside the mounting recess. A hole has been provided for a 2-56 fixing screw to prevent the coupler from being pulled out. Note that the maximum length of the screw is 4.25 mm, so it is likely the screw will have to be cut to length. Provided a metal screw is first used to create a thread in the provided hole, a nylon screw (e.g. Kadee #256) can be used for the permanent fixing. A nylon screw is much easier to cut to the desired length, and the Kadee nylon screws have a low profile head which provides maximum clearance for the outboard axles.

Kadee nylon 2-56 screws are available from good hobby shops.

Note that the height from rail level to the top of coupler mounting surface should be 11.5 mm, the standard for Kadee couplers.

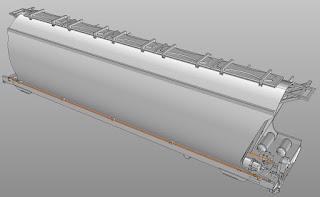

Brake Rods

|

| Brake Rods - 2 out of 3 shown. |

Note that cleaning out the hole in the longer of the two brake levers is a bit tricky, due to its location under the sloping end of the hopper. This hole has been printed at 0.6 mm but will probably still need cleaning out. One option is to use a length of 0.4 mm brass wire, approx. 75 mm long, held in a pin vice as a crude drill, by cutting one end at approx. 45 degrees to form cutting surfaces. This long "drill" can then be poked through the gaps in the supports for the roofwalk (prior to fitting the roofwalk, of course) to reach the hole in the brake lever. Another, perhaps better, alternative is to use a purpose-made cutting broach, such as the ones available from DCC Concepts. These have a long, tapered cutting blade which can be used for enlarging small holes. The second smallest broach in the DCC Concepts set is a suitable size for this application, as the diameter near the tip is just over 0.4 mm.

|

| Cutting Broaches |

The holes for the long brake rod, which links the two brake levers, theoretically, measure 137.4 mm centre-to-centre. This brake rod should have a 90-degree bend at each end, approx 1 mm long to fit in the holes. Because of variations in the 3D-printing process, the actual length required may vary slightly, so some fitting will be required. When the brake rod fits between in the holes at each end, it should be secured in place with superglue and also glued to the 5 support brackets along the side of the wagon.

The two short brake rods should each be approx. 12 mm long, with a 90-degree bend at one end, approx. 1 mm long. The straight end fits in the hole provided in the end of the hopper and the bent into fits into the corresponding brake lever.

Handrails

The WW has an inverted U-shaped handrail at the end near the handbrake, and a pair of vertical handrails at the opposite end. In addition, the AGWY/AGSY has 2 more pairs of vertical handrails at other corners. Small starter holes have been provided to locate handrails, which should be drilled out, e.g. with a 0.45 mm drill bit in a pin vice.

The handrails can be formed from 0.4 mm brass wire. The U-shaped handrail is 6 mm wide (centre to centre) and 8.5 mm high, which allows for 1 mm to be inserted into the holes. The vertical handrails are also 8.5 mm high.

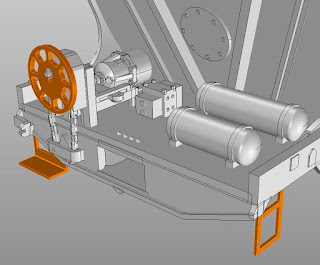

Door Operating Mechanism Rods (optional)

As an optional detail item, small holes have been provided for three rods which form part of the door operating mechanism on the real WW's. The holes should be cleaned out with a 0.45 mm drill bit, after which the rods can be cut from 0.4 mm brass wire and glued into position. The hole through the larger gear wheel should be drilled out 0.65 mm for 0.6 mm brass wire.

From left to right, as pictured below, the lengths of the rods are approx. 14.5, 15, and 13.5 mm, the last one being 0.6 mm wire.

From left to right, as pictured below, the lengths of the rods are approx. 14.5, 15, and 13.5 mm, the last one being 0.6 mm wire.

Air Brake Hoses

Uncoupling Levers

After positioning each uncoupling lever, check that the coupler can swing freely and is not obstructed, prior to gluing it into position.

Filling Discharge Door Openings (optional)

If desired, the rectangular holes in the bottom discharge doors can be filled with pieces of styrene sheet. Suggested dimensions are 5 mm x 9 mm x 0.5 mm thick. Small ledges have been provided inside the openings for this purpose.

It was necessary to leave these holes open for the 3D-printing process (stereolithography) to allow the unused liquid plastic resin to drain from the interior of the hopper.

Etched Brass Parts

The supplied etched parts consist of:

- roofwalk and ladder assembly

- brake wheel

- small steps (x3)

- large step

For all of the etched parts, the first step is to cut them free from the "fret", e.g. using a knife. The small attachment points are etched half way through to make cutting easier. Note that this will dull the knife blade, so don't use a new blade (or use a "snap-off" blade and discard the dulled blade.

Using a small file, remove any roughness at the attachment points and clean up any other areas requiring attention. Sometimes, due to variations in the etching over the entire sheet, small sections of very thin brass can remain but these are easy to clean up.

Roofwalk and Ladders (WW only, not AGWY/AGSY)

The roofwalk has attached ladders which need to the folder "down" and handrails (both loop and straight) which need to he folder "up". Note that the etch is symmetrical so it doesn't matter which is up or down to start with.

While there are special tools available for precisely folding etched brass models, a pair of pliers with smooth jaws or a small vice will do a pretty good job.

|

| Completed folding, using a small vice. |

If using a vice, for example, the sequence of folding is as follows:

- Clamp the roofwalk with the ladder pointing up and the etch of the roofwalk level with the top of the jaws. For this step, the ladder can be roughly in the centre of the vice.

- Using an object with hard surface and sharp, square corners (such as the handle of a small "engineers" square), fold the ladder away from you. Take care to NOT fold the straight handrail at the same time, and try to get a nice, sharp fold. Fold to an angle of about 80 degrees, not the full 90 degrees.

- Fold the straight handrail towards you, this time to 90 degrees.

- Reposition the roofwalk in the vice so that the end of the main section of the roofwalk is level with the end of the vice jaws.

- Fold the loop handrail towards you, to 90 degrees.

- Repeat for the other end, taking care to match the directions of folding.

Adjust the fold angle of the ladders slightly, if necessary, to ensure the roofwalk sits level on the supports at the end of the wagon while the bottom of the ladders fits into the notches in the side sill.

When satisfied with the fit, glue the ladder in position with superglue. However, You may want to consider gluing the roofwalk on only after all other assembly work has been completed as the wagon needs to be handled with care once the roofwalk is fitted, to avoid damaging the handrails on top.

Steps (Same for WW and AGWY/AGSY)

The single, larger step should be fitted to the corner of the wagon nearest the handrake. The bottom end of the step has a half-etched fold line, and the top of the step should be folded in the opposite direction.

Note the step locations and orientation, as per the diagrams below. Glue the steps to the underside of the wagon with superglue.

|

| Step Locations - Handbrake End |

|

| Step Locations - Handbrake End (bottom view) |

Handbrake Wheel

Weighting

With the suggested Kadee bogies, the completed WW weighs approx. 60 grams. For this length wagon, the NMRA recommended weight is 110 grams, although some modellers feel that the NMRA weight recommendations are excessive. A total weight of somewhere between 90 and 100 grams is probably about right.

Either enamel or acrylic hobby paints can be used to paint the finished model. The model pictured has been painted with Testors Model Master Enamel colour "Gelb RLM 04". (Gelb is German for yellow!)

Back to Marbelup Models Home Page